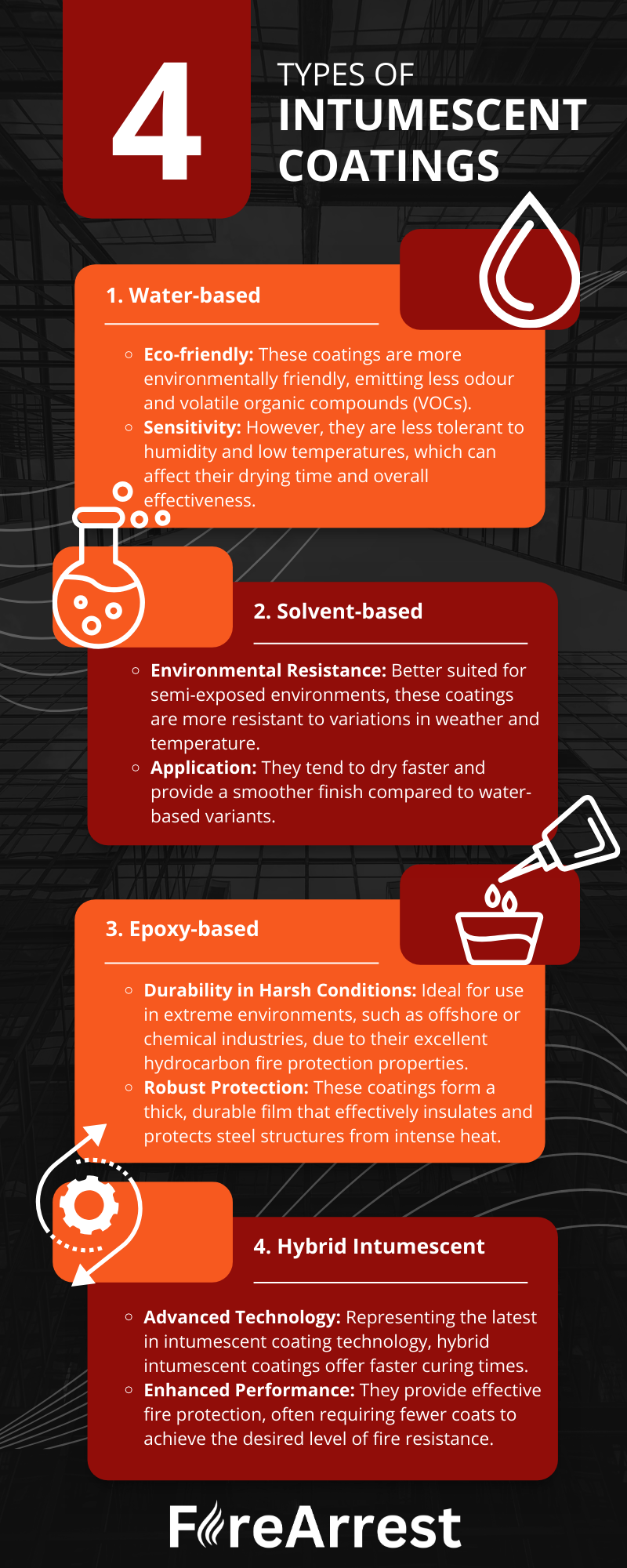

Intumescent coatings, commonly known as intumescent paint, play a crucial role in passive fire protection systems. These specialised coatings are designed to protect structures, particularly load-bearing elements, from the devastating effects of fire. Unlike active fire protection methods like sprinklers, intumescent coatings are a form of passive protection that remains inert under normal conditions but reacts when exposed to high temperatures.

How Do Intumescent Coatings Work?

Intumescent paints are engineered to respond to the intense heat of a fire. When the temperature rises to a certain threshold, typically around 200°C (392°F), the paint undergoes a chemical reaction. This reaction triggers the expansion of the coating, causing it to swell up to many times its original thickness. The expansion results in the formation of a carbonaceous char layer. This layer is comprised of a foam-like, insulating material filled with tiny, heat-resistant bubbles. The formation of this char is a critical aspect of the paint’s protective mechanism.

This char is a poor conductor of heat and effectively shields the material it covers, such as steel or timber, from the intense heat of the fire. By doing so, it significantly delays the time it takes for the material to reach its critical failure temperature, thereby preventing structural collapse and allowing more time for evacuation and firefighting efforts.