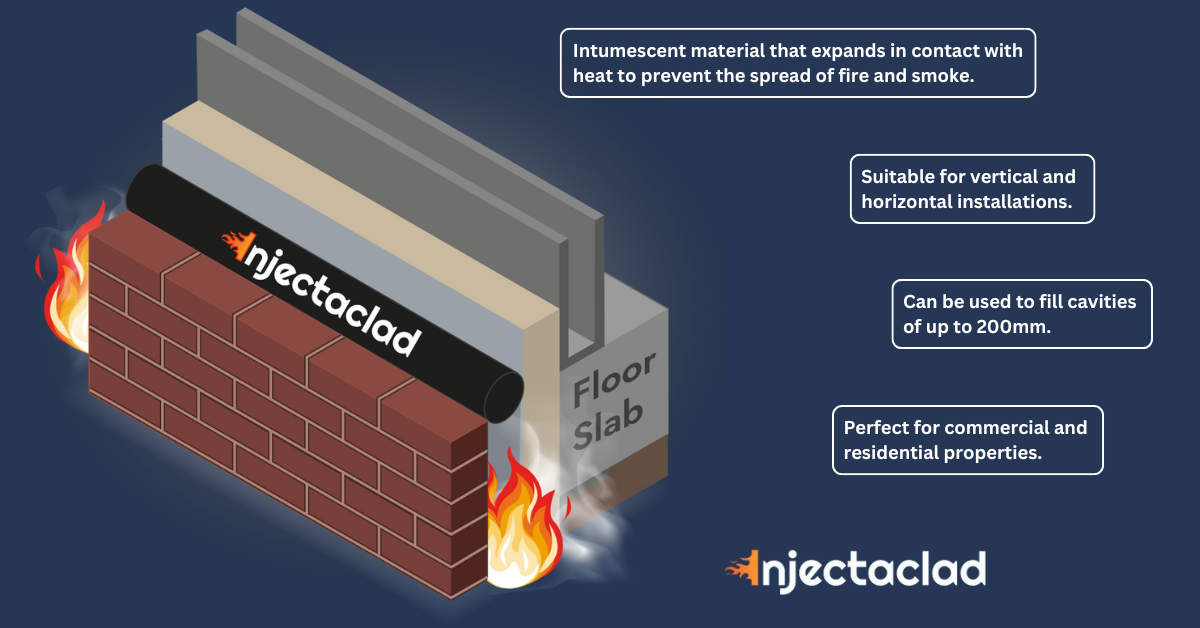

Injectaclad is an award-winning, intumescent acrylic-based, graphite sealant designed to enhance fire safety by sealing gaps in wall and floor cavities, creating an effective barrier against the spread of fire and smoke. Developed by experts in the field, Injectaclad is used extensively in both new constructions and retrofit applications to ensure compliance with fire safety regulations.

Why is Injectaclad Important?

Fire safety is a critical aspect of building design and maintenance. Injectaclad provides a reliable solution to prevent the rapid spread of fire and smoke through cavities, which can be a significant risk in multi-story buildings. By using Injectaclad, building owners and managers can improve the safety of occupants and comply with stringent fire safety standards.

How was Injectaclad Developed?

Injectaclad was developed through extensive research and collaboration among fire safety experts, engineers, and materials scientists. The goal was to create a versatile, easy-to-apply material that could effectively seal cavities in a variety of building structures.